As a member of the varsity soccer team these past few years, I have had the privilege of getting to use CHS’s world-class athletic facilities. I will be the first to tell you the money spent to build them is definitely tangible, which is why it amazes me how poorly the turf at Murray Stadium is kept.

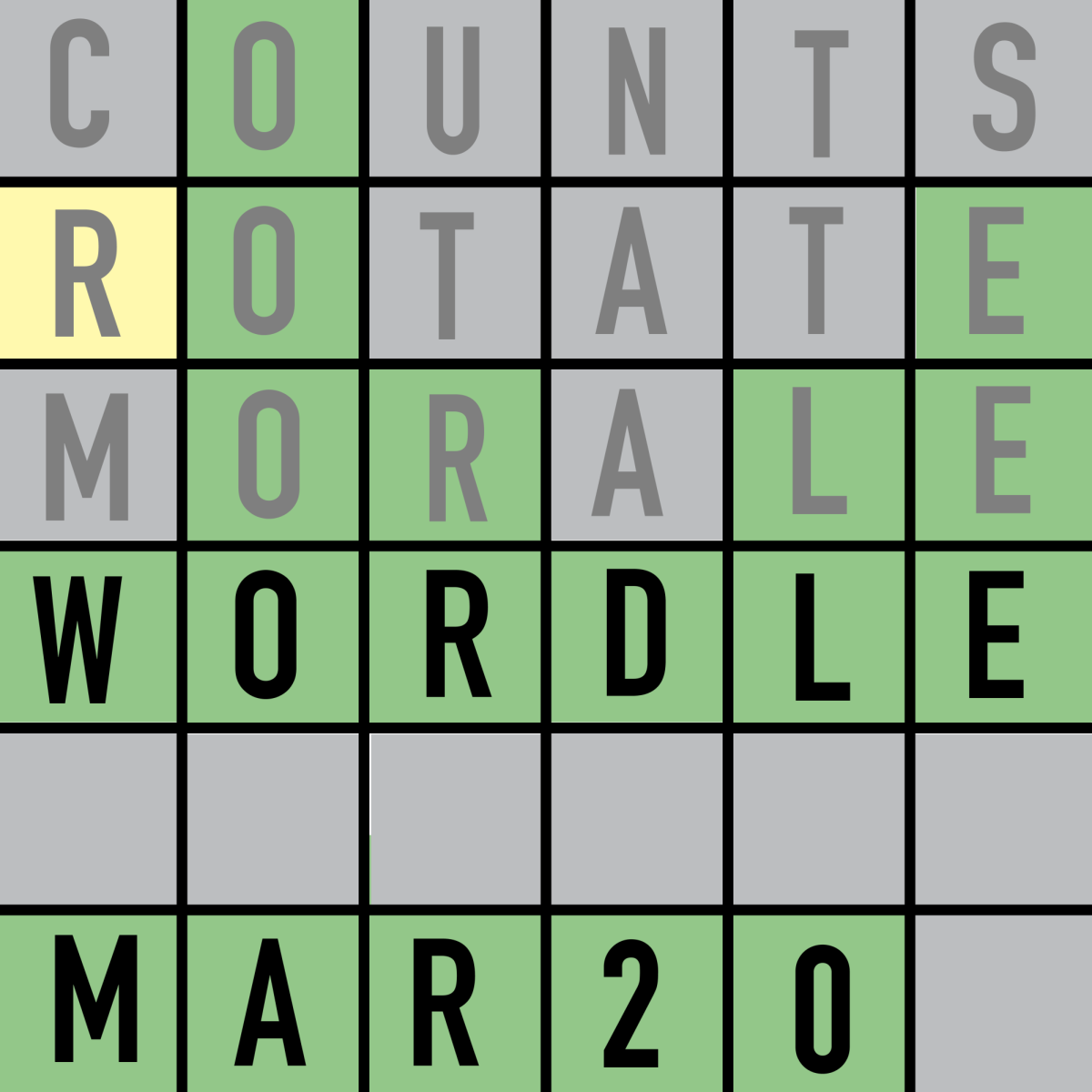

CYNTHIA YUE / GRAPHIC

I have played soccer since I was six years old. Having played hundreds of games in at least 10 states, there isn’t a type of soccer field that I haven’t seen. You name it; I’ve played on it. Astroturf, synthetic turf, some 30,000 different types of grass fields, and even some hybrid fields which contain both turf and grass. No matter where I’ve been, the quality of the field is a big part of the pregame discussion. Is it slick? Does the ball stick? Or does it move like it’s on a carpet? How bad are the dry spots on the field? Does the ball keep bouncing up on you? The quality of the fields varies wildly, but typically, turf fields are better, which makes sense considering grass is much harder to maintain, which is why all the soccer players were excited about the installation of turf at Murray.

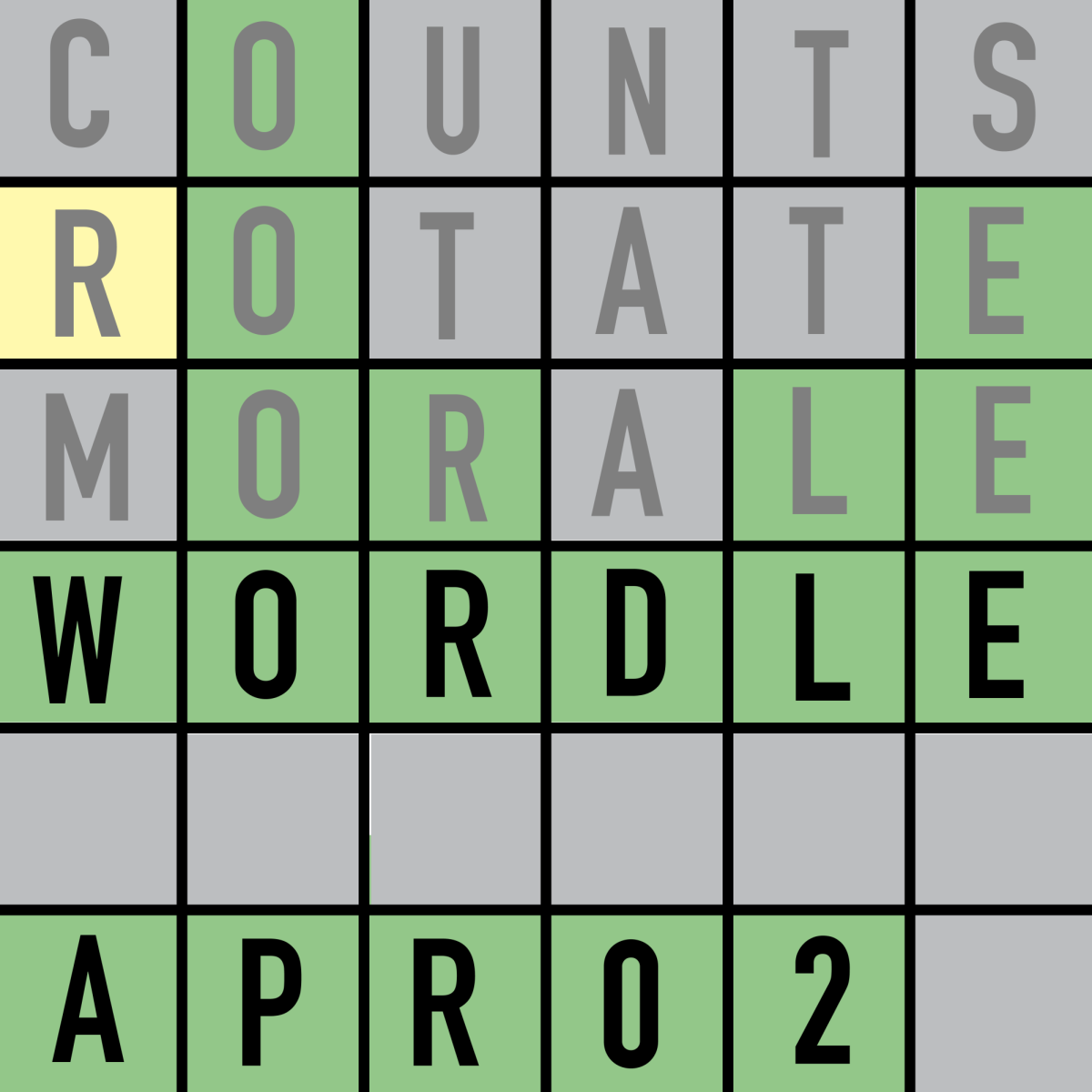

The turf was installed last year, and it received plaudits from myself, my teammates, the coaches and even the opposing teams. It was the supposedly the best playing surface in the state. However, there has been a noticeable drop off in the quality of the turf this year. It has been a year since the installation, and already the ball just flies on it, whereas last year it felt more like a well-manicured grass field, which is the goal of every turf field. The turf even looks different from last year, like it’s been worn out. But it shouldn’t. Turf fields are supposed to have a good eight to 14 years of quality usage, according to the manufacturer.

While it may seem like something negligible, the quality of the turf is important. Perhaps, as a goalkeeper, I am more attuned to the changes I’ve observed. As is typical of most goalkeepers, half of my warm-up time is spent walking the field, looking for any trouble spots and just simply testing all the different bounces the ball could take. This may not seem important until you give up the game-winning goal in a state tournament because of an unusual and unexpected bounce. It’s the same for field players, too. The ball seems to move a lot faster this year at Murray, and the players have had to adjust to that.

Sprinturf, the company from which CHS purchased the turf, stresses that field maintenance is extremely important, so much so, that they even provide maintenance training to those who purchase their fields and referrals for proper maintenance equipment. Sprinturf determines how often your field needs to be raked based on usage. According to its statistics, Murray should be raked about once a week. That way it will keep “your fibers standing tall and give the field a plush appearance.” But as I look at the turf at Murray this year and compare it to last year, I question whether or not those fibers are still “standing tall” or if it has the same “plush appearance.”

Athletics Director Jim Inskeep says the field gets raked once a week, and I have no reason to doubt that information. Assuming then that the field is maintained properly according to Sprinturf’s instructions, why has the quality of the turf taken a nosedive? Is it raked improperly? Do we have the right equipment to maintain the turf? Is there a defect in the turf at Murray? Any of these issues can be addressed quickly and definitively to troubleshoot and rule out other areas. Again, as a goalkeeper who has a unique tie to every nuance of the turf, it’s important to look closely at these concerns.

The Murray field is only a year into its eight to 14-year lifespan. So it’s important to acknowledge these imperfections as quickly as possible before they potentially get worse. A new field is a big investment, and it’s one that we should check up on before it’s too late.

The views in this column do not necessarily reflect the views of the HiLite staff. Reach Adam Gostomelsky at agostomelsky@hilite.org.

![AI in films like "The Brutalist" is convenient, but shouldn’t take priority [opinion]](https://hilite.org/wp-content/uploads/2025/02/catherine-cover-1200x471.jpg)

![Review: “The Immortal Soul Salvage Yard:” A criminally underrated poetry collection [MUSE]](https://hilite.org/wp-content/uploads/2025/03/71cju6TvqmL._AC_UF10001000_QL80_.jpg)

![Review: "Dog Man" is Unapologetically Chaotic [MUSE]](https://hilite.org/wp-content/uploads/2025/03/dogman-1200x700.jpg)

![Review: "Ne Zha 2": The WeChat family reunion I didn’t know I needed [MUSE]](https://hilite.org/wp-content/uploads/2025/03/unnamed-4.png)

![Review in Print: Maripaz Villar brings a delightfully unique style to the world of WEBTOON [MUSE]](https://hilite.org/wp-content/uploads/2023/12/maripazcover-1200x960.jpg)

![Review: “The Sword of Kaigen” is a masterpiece [MUSE]](https://hilite.org/wp-content/uploads/2023/11/Screenshot-2023-11-26-201051.png)

![Review: Gateron Oil Kings, great linear switches, okay price [MUSE]](https://hilite.org/wp-content/uploads/2023/11/Screenshot-2023-11-26-200553.png)

![Review: “A Haunting in Venice” is a significant improvement from other Agatha Christie adaptations [MUSE]](https://hilite.org/wp-content/uploads/2023/11/e7ee2938a6d422669771bce6d8088521.jpg)

![Review: A Thanksgiving story from elementary school, still just as interesting [MUSE]](https://hilite.org/wp-content/uploads/2023/11/Screenshot-2023-11-26-195514-987x1200.png)

![Review: "When I Fly Towards You", cute, uplifting youth drama [MUSE]](https://hilite.org/wp-content/uploads/2023/09/When-I-Fly-Towards-You-Chinese-drama.png)

![Postcards from Muse: Hawaii Travel Diary [MUSE]](https://hilite.org/wp-content/uploads/2023/09/My-project-1-1200x1200.jpg)

![Review: "Ladybug & Cat Noir: The Movie," departure from original show [MUSE]](https://hilite.org/wp-content/uploads/2023/09/Ladybug__Cat_Noir_-_The_Movie_poster.jpg)

![Review in Print: "Hidden Love" is the cute, uplifting drama everyone needs [MUSE]](https://hilite.org/wp-content/uploads/2023/09/hiddenlovecover-e1693597208225-1030x1200.png)

![Review in Print: "Heartstopper" is the heartwarming queer romance we all need [MUSE]](https://hilite.org/wp-content/uploads/2023/08/museheartstoppercover-1200x654.png)